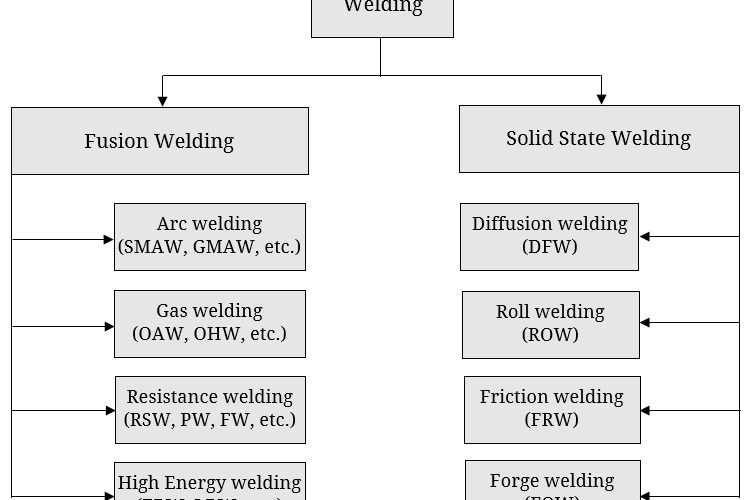

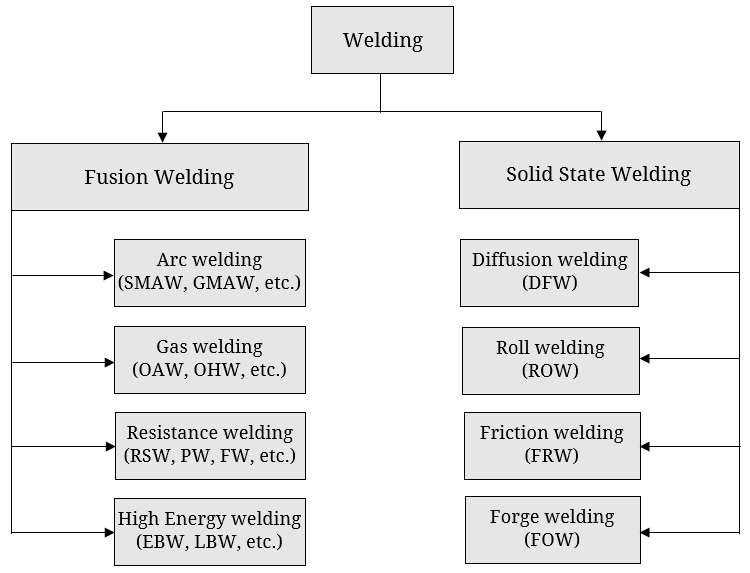

Requirement for joining of two or more components is inherent to manufacturing. There exist various joining techniques to assemble a wide variety of materials in multifarious ways. Some of these processes provide permanent joints, while others provide temporary joints. Like riveting, coupling and adhesive bonding, welding is also one permanent joining process. By definition, welding is one of the joining processes by which two or more solid components can be joined permanently by coalescence formation with or without the application of external pressure, heat and filler metal. So both heat and pressure are not mandatory for the sake of joining by welding; in fact, they are applied alternatively. So in some welding processes external heat is applied; while in other processes external pressure is applied. On this ground, welding processes can be broadly classified into two groups—fusion welding and solid state welding.

In all those welding processes where sufficient heat is applied from external source for fusion or melting of faying surfaces of the base components in order to form weld bead are termed as fusion welding processes. No pressure is usually desired in such processes. All arc welding, gas welding and resistance welding processes come under fusion welding. It is also worth mentioning that melting of faying surfaces of base plate occurs due to direct application of heat and not as a consequence of pressure, friction, etc.

On the other hand, in solid state welding processes, no heat is applied directly; instead sufficient pressure is applied in most cases. As a consequence of pressure, heat may generate at contact zone; however, usually this temperature remains well below the melting point of base components. Diffusion welding, forge welding, explosion welding, pressure welding, friction welding, etc. are examples of this category. Important differences between fusion welding and solid state welding are given below in table form.

Table: Differences between fusion welding and solid state welding

| Fusion Welding | Solid State Welding |

|---|---|

| In fusion welding processes, faying surfaces of base components melt down to form weld bead. | No such melting takes place; temperature of faying surfaces always remain below the melting point of parent material. |

| Heat is directly applied from some external means. However, pressure is not necessary. | No heat is directly applied to assist joining; instead, sufficient pressure is applied in most cases. |

| External filler material, if required, can be applied easily. | Solid state welding processes are mostly autogenous and also filler metal cannot be applied easily. |

| Broader heat affected zone (HAZ) exists surrounding the weld bead because of high heat input. | HAZ is narrow as no melting occurs. In most cases, HAZ is negligible and possesses no problem on welded structure. |

| Due to intense heating and subsequent melting, various mechanical and metallurgical properties are affected. | Mechanical and metallurgical properties are not affected severely. |

| Dissimilar metal joining by fusion welding is easier. | Dissimilar metal joining by solid state welding is very difficult. |

| High distortion takes place because of excessive heat input. Proper fixture must be employed to avoid it. | Level of distortion is low and usually does not require precautions to avoid it. |

| All arc welding, gas welding, resistance welding and intense energy welding processes are fusion welding. | Diffusion welding, pressure welding, roll welding, cold welding, friction welding, forge welding, etc. are examples of solid state welding. |

Melting of faying surfaces: As the name suggests, in fusion welding, faying surfaces of the parent component are allowed to fuse in order to create weld bead or coalescence. Filler metal, if applied, also melts down and mixes with molten parent metal. Contrary to this, no fusion or melting takes place in solid state welding and thus joining takes place while the components are in solid state. Although due to simultaneous application of pressure and friction, temperature of parent components may increase; however, it always remains below the melting point of base metal and thus no fusion occurs. In fact, this is the main difference between two types of welding.

Application of heat and pressure: It is obvious that heat must be applied from external source in fusion welding. This heat source can be of different types like electric arc in case of arc welding, burning of oxy-fuel gas in case of gas welding, electric resistance heating in case of resistance welding and even an intense energy beam like plasma, laser or electron beam in case of PAW, LBW or EBW. On the other hand, solid state welding processes usually require application of pressure. No direct application of heat is desired; however, heat may produce as a consequence of pressure, friction, etc.

Application of filler material: Filler material is desired to fill the root gap that exists in between parent components. Based on application of filler and its composition, welding can be classified into three categories—autogenous, homogeneous and heterogeneous. When root gap is very small then filler is not required and such process is termed as autogenous. Solid state welding are usually performed in autogenous mode. On the other hand when filler is applied and metallurgical composition of filler is similar to that of parent metal, it is termed as homogeneous welding; while if metallurgical composition of filler is different from that of parent metal, it is called heterogeneous welding. Fusion welding can be advantageously performed in all three modes; however, extra precautions and optimum parameters must be utilized for joining in heterogeneous mode.

Presence of HAZ: Heat Affected Zone (HAZ) is the narrow layer in the welded components surrounding weld bead where material has not been melted but various physical and mechanical properties have been affected due to heating and subsequent cooling. This HAZ is considered as weak region as it is highly susceptible to mechanical and chemical failure. Due to extreme heating at a temperature above melting point of concerned material, broader HAZ exists surrounding the weld bead when components are joined by fusion welding processes; whereas a narrow (sometime negligible) HAZ can be observed when components are joined by solid state welding processes as lesser heat generates during welding.

Changes in mechanical and metallurgical properties: Various metallurgical properties like grain orientation, grain structure, atomic defects, etc. are usually affected during welding. Many mechanical properties like strength, hardness, toughness, etc. are also affected as a consequence of metallurgical changes. Usually such changes are associated with level of heating and subsequent cooling of components. In fusion welding processes high heat is applied and materials are melted, so such processes can alter various properties to an extreme level. Contrary to this, such changes are meagre and mostly within acceptable limit when joining is performed using solid state welding processes.

Capability of dissimilar metal joining: One of the biggest advantage of welding among all joining processes is leak-proof and sound joining of dissimilar materials. However, every welding process is not suitable for this purpose. Since dissimilar metal joining is basically heterogeneous welding, so only few fusion welding processes can fulfill this requirement. However, it requires extreme care and optimum process parameters to obtain sound joint. Solid state welding is not suitable at all for dissimilar metal joining.

Level of distortion in welded structures: Due to uneven expansion and contraction during heating and cooling in welding, the assembled structures distorts to a different plane leading to welding defect. Such distortion in joined structures causes dimensional inaccuracy and rejected parts. Distortion tendency in welded structures increases with the increase in heat input. So if proper fixture is not employed or proper distortion minimization technique (like skip welding, pre-setting the parts in opposite direction, etc.) is not adopted, then fusion welded parts show higher distortion than the other one as heat input is higher in former case.

Examples of the processes: All arc welding processes (MMAW, GMAW, TIG, SAW, FCAW, ESW, etc.), gas welding processes (OAW, OHW, AAW, PGW, etc.), resistance welding processes (RSW, RSEW, PW, PEW, FW, etc.) and intense energy beam welding processes (PAW, LBM and EBW) are examples for fusion welding. Diffusion welding (DFW), pressure welding (PW), roll welding (ROW), cold welding (CW), friction welding (FRW), forge welding (FOW), etc. are examples of solid state welding.

Scientific comparison among fusion welding and solid state welding is presented in this article. The author also suggests you to go through the following references for better understanding of the topic.

- Difference between fusion welding and solid state welding by difference.minaprem.com.

- Welding Defects by M. Preto (1st edition, Aracne).

- Physical Chemistry of Fusion Welding by G. F. Deyev and D. G. Deyev (1st edition, DGD Press).