Machining or metal cutting is one of the secondary manufacturing processes by which excess material is gradually removed from a preformed blank to obtain desired shape, size and finish. There exist larger number of processes to fulfil the basic requirement of machining. Such processes can be broadly classified as conventional machining processes (turning, threading, facing, drilling, boring, shaping, planing, milling, grooving, reaming, etc.), abrasive cutting processes (grinding, lapping, honing, polishing, superfinishing, etc.), micro-precision machining processes (micro-milling, micro-drilling, diamond turning, etc.), and non-traditional machining processes (ultrasonic machining, electro-discharge machining, electro-chemical machining, laser beam machining, ion beam machining, hybrid machining, etc.).

All of these are subtractive manufacturing processes, which indicates layer by layer material is removed from a solid workpiece to obtain desired three dimensional features; however, they follow varying principles of material removal and thereby possess varying capability in terms of machinable materials, stock removal rate, surface quality, production rate and cost, etc. Most NTM processes and micro-precision machining processes are not suitable for removing bulk volume of material; instead, they can generate fine features with high accuracy. Conventional machining processes are suitable for high stock removal as well as imparting reasonably good surface quality. However, achieving both in a single pass is not possible. Thus machining is usually carried out in two steps with varying process parameters (cutting velocity, feed rate and depth of cut).

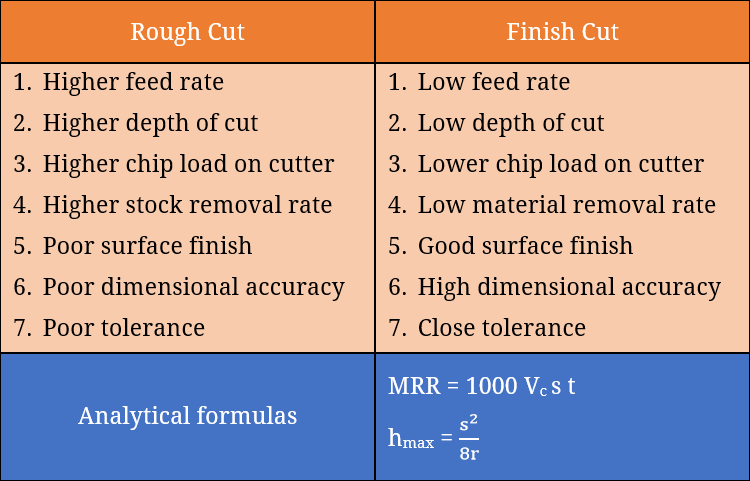

In first step, bulk amount of material is quickly removed from workpiece as per required feature. Higher feed rate and depth of cut are employed for this step so that high stock removal rate is obtained. This step is called rough cut or roughing pass. It cannot provide good surface finish and close tolerance. After rough cut, a finish cut or finishing pass is carried out to improve surface finish, dimensional accuracy and tolerance level. Here very low feed rate and depth of cut are employed. So stock removal rate reduces in finish pass but surface quality improves. Various differences between roughing and finishing in conventional machining processes are given below in table format.

Table: Differences between roughing and finishing

| Roughing | Finishing |

|---|---|

| Objective of rough pass is to remove bulk amount of excess material from workpiece in every pass. | Objective of finish pass is to improve surface finish, dimensional accuracy and tolerance. |

| Higher feed rate and depth of cut are utilized. | Very low feed rate and depth of cut are utilized. |

| Material removal rate (MRR) is high. | MRR is comparatively low. |

| Surface roughness after rough pass is more; thus surface finish is poor. | Surface roughness after finish pass is low; and thus surface finish is good. |

| It cannot provide high dimensional accuracy and close tolerance. | It can provide high dimensional accuracy and close tolerance. |

| An old cutter can be utilized for roughing pass. | Sharp cutter is highly desired to achieve good finish. |

| It is performed prior to finish pass. | It can be performed only after rough pass. |

Objectives of rough cut and finish cut: Rough cut is carried out to quickly impart a basic shape according to desired feature. Here surface roughness is not important factor; instead, removing maximum unwanted material is ultimate objective. Contrary to this, finish pass is carried out to improve surface finish, dimensional accuracy and tolerance of the desired feature. Stock removal rate has no importance in case of finish pass.

Process parameters and MRR: Cutting velocity (Vc), feed rate (s or f) and depth of cut (t or a) are three process parameters for every conventional machining process. These parameters greatly influence overall machining action and capability. Higher velocity, feed and depth of cut can increase material removal rate (MRR) but with the sacrifice of surface finish. MRR is proportional to velocity, feed and depth of cut and thus can be mathematically expressed by the multiplication of velocity, feed and depth of cut with a positive constant for unit conversion. During machining, velocity is normally maintained unchanged as it is selected on the basis of work and tool material, machine tool capability, vibration level and other important factors. To fulfil the basic objective, higher feed and depth of cut are employed in rough pass and as a consequence MRR increases. On the other hand, low feed and depth of cut are employed in finish pass and thus MRR reduces.

Surface finish and dimensional accuracy: Presence of scallop marks or feed marks on the finished surface is inherent to every conventional machining process due to feed velocity. Such saw-tooth alike scallop marks cause primary surface roughness. Apart from cutting tool geometry, surface roughness directly relies on feed rate. Higher feed rate can lead to poor surface finish. Higher depth of cut also tends to degrade surface finish and machining accuracy. In rough cut, higher feed and depth of cut are utilized and thus poor surface finish is obtained. It also fails to provide high dimensional accuracy and close tolerance. On the other hand, finish pass can improve finish, accuracy and tolerance as very low feed and depth of cut are employed.

Usage of old cutter: An old cutter may have less sharp edges (i.e., higher edge radius and nose radius) as it has already worn out during machining. Edge and nose sharpness limit the achievable surface finish in the process. A sharp edge cannot take high chip load but is mandatory to obtain better finish and accuracy. So an old cutter can be utilized in rough pass without noticeable problem as surface quality does not matter. However, a sharp tool should be used in finish pass so that better finish, accuracy and tolerance is achieved. Here feed and depth of cut remain low, so chip load possesses no detectable problem in tool breakage or edge chipping.

Scientific comparison among roughing and finishing in machining processes is presented in this article. The author also suggests you to go through the following references for better understanding of the topic.

- Machining and Machine Tools by A. B. Chattopadhyay (1st edition, Wiley).

- Manufacturing Engineering and Technology: SI Edition by S. Kalpakjian and S. R. Schmid (7th edition, Pearson Ed Asia).