Manufacturing is one crucial step in production that actually converts raw materials or scraps into desired products by adding substantial value. Several manufacturing processes exist to cater the need of processing wide variety of materials in sweeping ways. Growing need for miniaturized products with better surface quality and more inbuilt functionalities paved the way for rapid development of manufacturing and as a consequence various sophisticated processes have evolved that can efficiently process materials to better fulfil today’s market demand. Scope of the manufacturing has also expanded gradually to cover up a vast domain ranging from age old industrial sectors to advanced product or service based companies to adequately contribute towards their requirements.

Various proponents attempted to classify all manufacturing processes in a systematic way; however, in many cases, such classification fails to unambiguously encompass newly developed processes. Considering all relevant processes, manufacturing can be categorized in following five groups:

Casting processes: Here raw material is melted to pour into a pre-built cavity and the same allowed to undergo solidification. Thus product with inverse shape of the cavity is obtained. This age-old process is suitable for providing a basic shape to the component as it can neither produce intricate shapes nor give smooth surfaces. All casting and molding processes (like sand mold, die casting, injection casting, etc.) follow this basic principle.

Joining processes: Here two or more solid components can be joined either temporarily or permanently. Joining can be accomplished either by melting to form a coalescence or with help of other mechanical elements. Welding, riveting, soldering, brazing, coupling, fit joining, adhesive bonding, fastening, cotter joint, knuckle joint, etc. come under the umbrella of joining. Disassembly processes also come under this.

Modification processes: Here material properties or basic shape can be altered by various means to better match the requirement. Various forming processes like forging, rolling, drawing, extrusion, etc. are used for shape transformation; while, heat treatment, cryogenic treatment, coating, etc. are used to modify properties of the components.

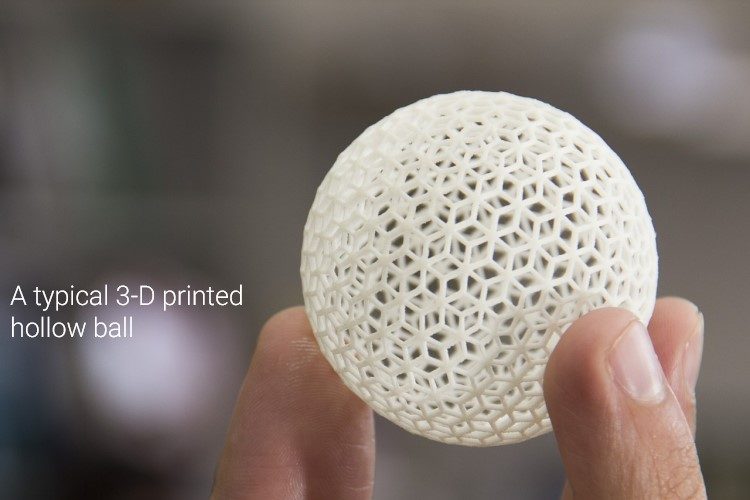

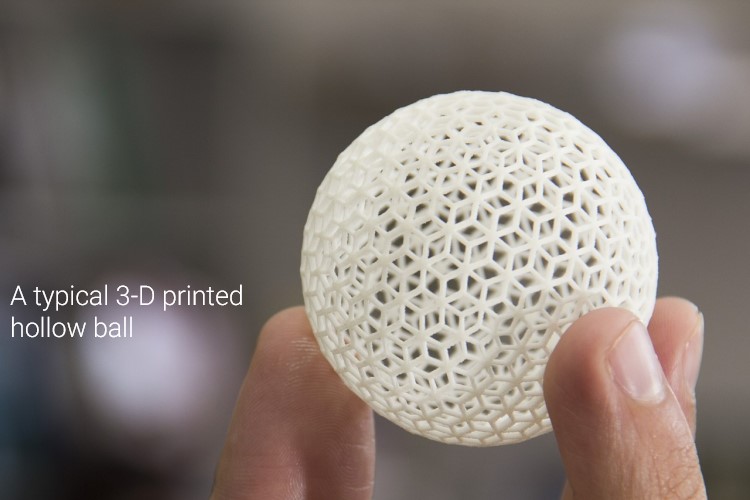

Additive processes: Here layers of material in semi-solid form are added one over another to directly build a true three dimensional component having required features and enhanced accuracy. Thus it eliminates requirement of post-processing; however, such processes are suitable for small size components. Rapid prototyping processes (like 3-D printing, stereo lithography, selective laser sintering, etc.) follow the additive principle.

Subtractive processes: As the name suggests, here layer by layer material is removed from the solid workpiece to finally produce intended product. So material wastage takes place. Machining or metal cutting processes follow subtractive principle. Examples include turning, shaping, milling, drilling, grinding, lapping, abrasive jet machining, electric-discharge machining, laser beam machining, etc.

Table: Differences between additive and subtractive manufacturing

| Additive Manufacturing | Subtractive Manufacturing |

|---|---|

| Here layers of material are added one over another to build 3-D component. | Here layers of material are removed from a solid block to obtain desired 3-D component. |

| It is suitable for materials having low melting point. | Melting point usually does not pose any restriction on it. |

| Volumetric density of the working material can be altered during operation. | Volumetric density of the working material cannot be altered during operation. |

| No material wastage takes place. | Material wastage occurs in various forms like chips, vaporization, etc. |

| Additive processes are suitable for a narrow range of materials. | Subtractive processes pose no restriction on working material. |

| It is suitable for small size components. It cannot accommodate large components. | It can process small to large objects. |

| Any complex shape can be directly produced by these processes. | Component complexity imposes restriction on its feasibility. |

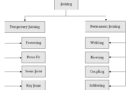

| Fully enclosed internal hollow parts can be fabricated easily. | Fully enclosed cavity cannot be produced. |

| Additive processes are time consuming and require sophisticated equipment, experienced worker, and tight environment control. | Subtractive processes are time efficient, economically cheaper and ergonomically relaxing. |

Addition and subtraction philosophy: Both the philosophies are used to produce true three dimensional components or features with enhanced dimensional accuracy and close tolerance; however, they differs in their approaches. Additive manufacturing follows the principle of adding layer by layer material one over another as per the design to finally build the product having intended features. So the process starts with zero height (no material) and gradually its height builds up as layers are deposited. Material is usually deposited in semi-solid form and next layer is added once the previous layer becomes fully dry. Contrary to this, in subtractive manufacturing philosophy, layer by layer material is removed from desired location of a solid block to finally obtain desired component. So the process starts with a solid raw material block and material is removed from it to create intended features. Material can be removed in several ways (like shearing in the form of solid chips, melting and vaporization, ionization, sputtering, etc.) based on the process employed.

Melting point of working material: With additive processes, working material is either required to melt down or make it plastic by heating. Material with higher melting point will consume more heat to become plastic (semi-solid) so that it can be added over previous layer. Thus it is preferred for low melting point materials like plastic or PMMA. However, melting point is not a considerable factor for processing engineering materials by subtractive methods as material is removed in solid form or by ionization. In such thermal energy based NTM processes where material is removed by melting and vaporization, the beam energy intensity always remains excessively higher than melting point of materials. For example, in EDM, localized temperature exceeds 10,000°C, which is much higher than 3422°C (melting point of titanium, highest melting point among all metals).

Manipulating volumetric density: Biggest advantage of additive processes is the possibility of altering density of working material during deposition of layers. Here density in a range of 20 – 100% can be adopted and overall material volume can be changed in a controlled way. This in one way can reduce material consumption and in other way can substantially reduce component weight, mostly without sacrificing wall strength. Such a facility cannot be obtained with subtractive processes, as density of working material remains same throughout the operation. Thus weight of the component cannot be reduced once the basic starting material block is selected.

Wastage of material: With additive processes, a thin layer of material is added over previous layer as per design (computer based design, like CAD). So when there is any cavity or slot like feature, then material is not deposited on that position. Repeated deposition of material in layers according to the design ultimately produces intended 3-D object. No further post-processing is performed on it; so no material wastage occurs. With subtractive processes, excess material is gradually removed from basic raw material; however, such removal may occur in various forms (like solid chips, melting and vaporization, ionization, sputtering, etc.) based on process employed.

Suitability: Till now, with the fullest development of technology, additive processes are suitable for selective materials such as plastic and PMMA. Also it cannot handle larger objects; system capacity is usually limited to 2kg. However, subtractive processes can handle a wide variety of material. Certain mechanical, electrical and thermal properties (like hardness, brittleness, electrical conductivity, melting point, etc.) pose restrictions on machinability for a particular process, but such limitations can be overcome by employing another process. These processes are also capable of efficiently handling larger objects.

Production of complex shape and hollow parts: In additive processes, the CAD drawing is first sliced into thin layers (layer thickness depends on desired dimensional accuracy and surface finish) and then material is added layer by layer one over another. So any complicated shape can be considered during slicing and subsequent material deposition steps, and thus eliminates requirement of post processing. It can even produce internal hollow parts, like fully enclosed cavity. Subtractive processes has limited capability in producing complex shapes. It cannot create fully enclosed cavity.

Industrial aspects: Additive processes are time consuming as layer deposition time and thereafter drying time are associated with it. However, while fabricating small size objects having intricate shapes and high precision (for example prototype), it can be time and cost efficient, especially if quantity of production is very small. A tight workroom environment control is also desired in many cases. Although additive processes are emerging as suitable alternative for subtractive processes in certain areas, for mass production of large objects with simple shape, subtractive processes can overwhelmingly supersede the its rival.

Scientific comparison among additive manufacturing and subtractive manufacturing is presented in this article. The author also suggests you to go through the following references for better understanding of the topic.

- Additive Manufacturing of Metals: The Technology, Materials, Design and Production by L. Yang, K. Hsu, B. Baughman, D. Godfrey, F. Medina, M. Menon and S. Wiener (1st edition, Springer).

- Additive Manufacturing: 3D Printing for Prototyping and Manufacturing by A. Gebhardt and J. Hötter (1st edition, Hanser).

- Newman et al. (2015); Process planning for additive and subtractive manufacturing technologies; CIRP Annals; Vol. 64 (1); pp. 467-470.