Primary objective of manufacturing is to convert raw materials or scraps into desired consumer products by adding substantial value to it. Such conversion may not always possible in single step and usually requires multiple steps where each step incorporate certain functionalities into the product. There exist various manufacturing processes including age oil processes like casting, forming, joining, machining, and surface working and also newly developed processes like rapid prototyping and powder metallurgy. Each of these processes has different capability in terms of functionalities, feasible feature, work material, surface quality, etc. So joining is one manufacturing process that is used to assemble solid components.

What is joining? Why it is required?

Joining is a part and parcel to every manufacturing process as it facilitates easy, efficient and economic fabrication of products. Complex shaped objects or high quality objects cannot be produced directly by casting. For research purposes or prototype development costly casting methods (like investment casting) can be employed to directly obtain desired product; but such a strategy will not be economical in industrial aspect where large scale production is required. To maintain production cost minimum, a basic shaped object is primarily made by casting and further processing are performed on it to impart intended features and functionalities as well as to improve upon surface finish and dimensional tolerance. Joining is one such post-processing technique which is employed to assemble individual components or structures to ultimately build a larger one.

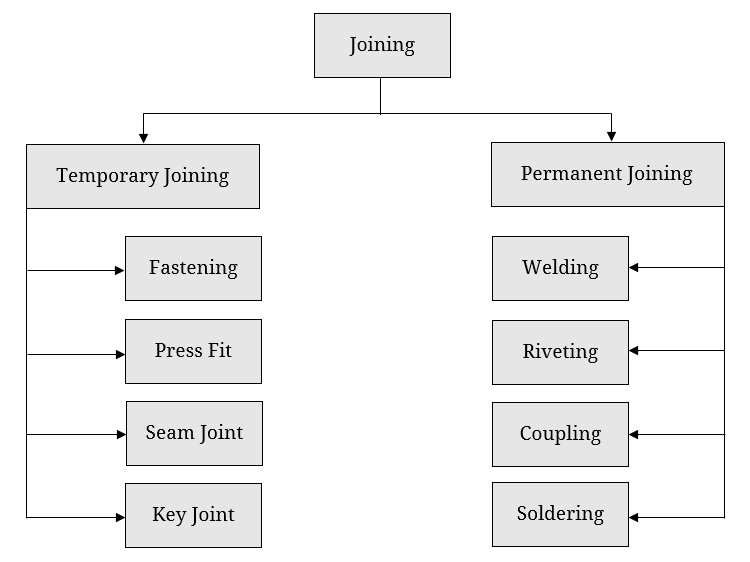

By definition, joining is one of the manufacturing processes that is used to assemble two or more solid components either temporarily or permanently. Joining can be realized by utilizing additional elements (such as filler metal, rivet, strap, nut-bolt, screw, cotter, key, etc.) and/or taking assistance of external input (such as heat, pressure, shock wave, etc.). Not only metals, joining can be carried out for plastic, ceramic and composite also. To join a wide variety of materials in several ways, there exist quite a few joining processes, which can be broadly classified into two categories—temporary joining and permanent joining.

Temporary joints—As the name suggests, such joints are not meant to keep fixed. Such a joint allows easy and quick dismantling of assembled structures without breaking them. It is beneficial for repairing, maintenance and inspection purposes. There exist few joining processes that offer temporary joints, which include fastening, press fit, key joint, cotter joint, knuckle joint and few adhesive joints.

Permanent joints—Such joints are meant to stay fixed for longer duration and don’t require frequent disassembly. Any dismantling of assembled structures can only be realized by rupturing the components. Thus it imposes restriction for repairing, maintenance and inspection. However, such joints are reliable, strong and leak-proof. They offer high load carrying capacity and longer performance. Joining processes that offer permanent joints include welding, soldering, brazing, riveting, coupling, most adhesives, etc.

What is fastening? It is a temporary joining process

Fastening is one temporary joining process that employs additional elements to mechanically assemble or attach two or more parts together. Additional mechanical elements that are used for fastening is called fasteners. However, threaded elements like nut-bolt, screw, etc. are commonly considered as fasteners as it can provide reliable and sound joint. The term fastening, however, encompasses a larger group of fasteners. Apart from threaded fasteners, clamp, clip, ring, button, chain, pin, nail, metallic latch, hook, lobster, rope, cable, hose, flange, buckle, etc. are also fastening elements.

How fastening differs from joining?

Joining is a generic term that indicates assembly of solid parts by any means. As mentioned earlier, there are various joining processes and each of them has different capabilities. Fastening is one temporary joining process that is overwhelmingly employed for non-permanent joining of metals and wood components. In conclusion it can be said that fastening is one type of joining process, others being welding, riveting, coupling, adhesive, etc.