Primary aim of secondary manufacturing processes is to obtain products having better surface quality, high dimensional accuracy and close tolerance. Such processes include machining or metal cutting operations (like turning, milling, drilling, reaming, precision turning, grinding, lapping, honing, AJM, USM, EDM, LBM, IBM, etc.) and surface modification operations (like heat treatment, coloring, coating, etc.). Each of these processes has varying level of capabilities in terms of surface quality and precision. Design for manufacturing also takes care of such capability to recommend a particular process based on available resources. Functional performances and reliable service life of a manufactured product greatly depend on its surface and sub-surface qualities. Moreover, surface quality is one crucial parameter that determines machinability.

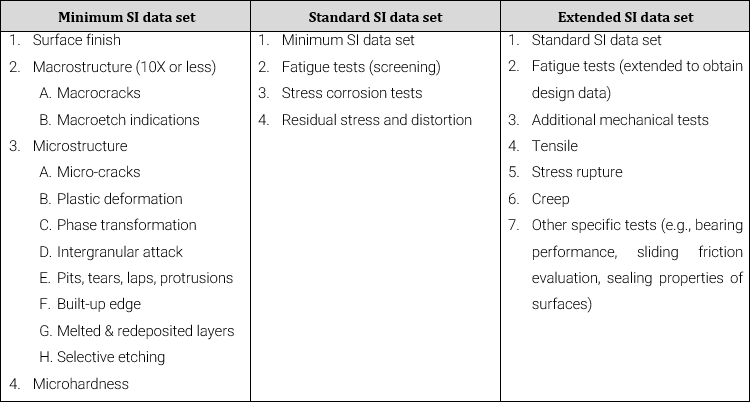

There exist few technical terms to characterize the quality and topography of a solid surface. Although many of such characteristic parameters are application related, there exist few guidelines for judging surface quality of manufactured product. Introduced by Field and Kahles in 1964, surface integrity (SI) encompasses all such parameters, as shown below. Surface finish is widely used element of integrity; in fact, it is most important aspect of assessing quality of as machined surface and sub-surface. In the context of machining, two terms—surface finish and surface roughness are commonly used to characterize the surface quality. Although they are used interchangeably, they are not scientifically same; however, they indicate same surface characteristics. Minimum, standard and extended surface integrity (SI) data set for a machined surface is depicted below.

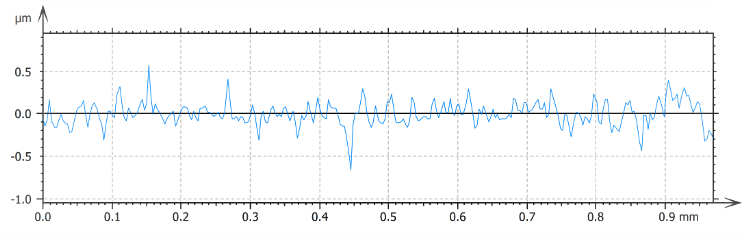

Surface roughness is the measure of macro and micro asperities and irregularities present on a finished surface after machining. It is the quantitative approach to find out height of peaks and depth of valleys of surface asperities. There are various instruments to facilitate such measurement. On the other hand, surface finish is the qualitative approach to designate the surface either by observing the surface or from the roughness value. Various attributes like bad, poor, good, glossy, fine, etc. are used to designate the finish quality. It does not fetch any numerical value and thus it is affected by human bias. Various differences between surface roughness and surface finish are given below in table format.

Table: Differences between surface roughness and surface finish

| Surface Roughness | Surface Finish |

|---|---|

| It is one quantifiable physical parameter and can be expressed using numerical value with unit. | It is not quantifiable parameter, instead a qualitative one. It can be expressed using attributes only. |

| It always has an absolute value. It is independent of application and also free from human bias. | It does not have absolute value. Mostly it relies on application and also affected by human bias. |

| Roughness can be measured directly using suitable instrument. | Finish cannot be measured. |

| Roughness of machined surface can also be estimated from relevant process parameters and tool features. | Surface finish cannot be estimated using mathematical formula. Value of roughness is used to indirectly specify finish. |

Qualitative and quantitative value: Every physical parameter is measurable and the measured value is expressed using numeric and corresponding unit. A quantitative measurement always fetch numerical value along with unit. Surface roughness is one quantifiable parameter. For example, average roughness of micro-milled surface is 325 nanometre. On the other hand, finish is one qualitative parameter and cannot be expressed using numerical value. Only attributes like good, bad, poor, rough, etc. are used for the this purpose.

Subjective parameter and human bias: Attributes used for surface finish is subjective and depend on application or intended result. A milled surface used for casing may have good finish; however, if similar milled surface is intended to use for ball-bearing, then it can be considered as poor finish. However, the roughness will remain same (may be around 5µm). So roughness is independent of application. It is also not affected by human bias. Humans are incommensurable; so a good finished surface to one person may not appear good to another person. Thus attributes used for specifying surface finish has limited application in scientific context.

Measurement by instrument: Surface roughness can be directly measured using suitable instrument. Now-a-days several instruments (contact or non-contact type) are readily available in the market—each having varying features and capability. Irrespective of measuring instrument, roughness is basically the measure of height of peaks and depth of valleys of the surface asperities. Surface finish cannot be measured using instruments; instead, value of surface roughness is utilized to indirectly specify finish.

Estimation using other parameters: Different manufacturing processes provide varying level of surface finish. Usually surface generation (machining) and surface modification (heat treatment, coating and coloring) processes tend to provide lower roughness. However, various newly developed or sophisticated processes like powder metallurgy and investment casting can also provide better quality surface. A list of typical roughness obtained in various processes is provided below. Roughness can be estimated using various process parameters and relevant features of instrument employed in the process. For example, in machining using a sharp tool, estimated roughness can be expressed using feed rate, principal and auxiliary cutting edge angles. However, surface finish cannot be estimated in such way.

Table: Typical surface roughness obtained in various processes

| Manufacturing process | Typical surface roughness (Ra) |

|---|---|

| Sand casting | 50 – 5µm |

| Die casting | 10 – 2µm |

| Investment casting | 5 – 2µm |

| Injection molding | 5 – 1µm |

| Powder metallurgy | 20 – 5µm |

| Rolling | 50 – 5µm |

| Forging | 30 – 2µm |

| Extrusion | 2 – 0.5 µm |

| Turning / milling | 20 – 2µm |

| Fly cutting | 5 – 1µm |

| Drilling | 10 – 2µm |

| Boring | 5 – 2µm |

| Reaming | 3 – 1µm |

| Broaching / hobbing | 5 – 0.5µm |

| Grinding | 2 – 0.5µm |

| AJM / AWJM / USM | 5 – 0.2µm |

| ECM / ECD / ECG / CHM | 2 – 0.1µm |

| EDM / LBM / EBM | 2 – 0.5µm |

| IBM | 500 – 100nm |

| Hybridized NTM | 200 – 20nm |

| Honing | 500 – 100nm |

| Lapping | 250 – 25nm |

| Burnishing/polishing | 200 – 20nm |

| Superfinishing | 100 – 10nm |

| Micro-milling | 500 – 100nm |

| Diamond turning | 200 – 20nm |

Scientific comparison among surface roughness and surface finish is presented in this article. The author also suggests you to go through the following references for better understanding of the topic.

- Surface Integrity in Machining edited by J. P. Davim (2010, Springer Science & Business Media).

- Surfaces and their Measurement by D. J. Whitehouse (2004, Elsevier).

- Nonconventional Machining by P. K. Mishra (2007, Narosa Publishing House).