Welding is one of the joining processes that can efficiently and economically assemble two or more metallic or non-metallic parts permanently. With the extensive development throughout the years, a large number of such processes has evolved in order to cater the need to join a large variety of materials in innumerable ways. Gas metal arc welding (GMAW) is one such process where metallic materials are joined permanently by melting faying surfaces of the components by means of electric arc established between electrode and workpiece. The consumable electrode, in the form of small diameter wire, is continuously fed at a predefined rate for depositing necessary filler metal to fill the root gap.

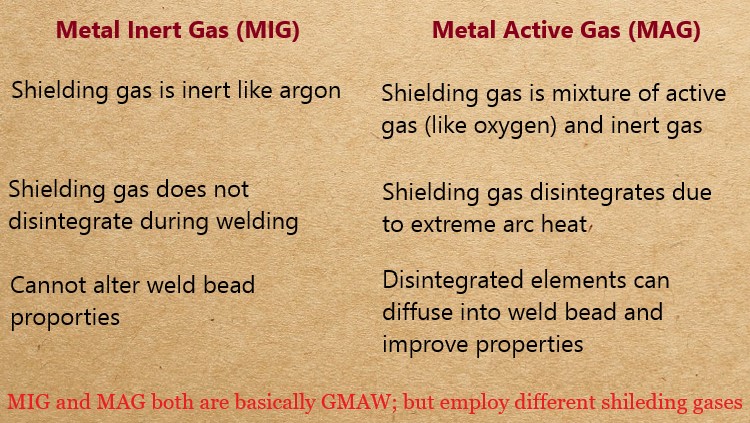

In order to stabilize the arc and also to protect the hot molten metal pool beneath this arc from oxidation and other contamination, proper shielding gas is used to shield or cover entire welding zone surrounding this arc. This shielding gas can be chemically inert one or can contribute in many relevant properties by actively participating in the welding process. Accordingly GMAW can be classified into two groups—Metal active gas (MAG) and Metal inert gas (MIG) welding. So MIG and MAG both are basically variants of GMAW process; only difference lies on the shielding gas used in those processes.

As the name suggest, Metal Inert Gas (MIG) welding process utilizes suitable inert gas for shielding purpose during welding. Such gas is mainly argon or helium, or a mixture of these two in different proportions. Since these gases are chemically inert thus they remain stable even at extreme arc heat. Therefore they do not contribute in altering any weld characteristics apart from protecting the weld bead and electric arc from any external influence.

On the other hand, Metal Active Gas (MAG) welding utilizes an active gas mixture as shielding gas. For example, a suitable mixture of carbon di-oxide (CO2) and oxygen (O2) along with other comparatively stable gases like argon, helium, nitrogen, etc. Besides fulfilling basic requirement of shielding gas, such active gases can break down due to arc heating and subsequently induce various chemical elements on weld bead that can enhance joint properties. It also contributes in stabilizing arc, reducing spatter level, etc. Various differences between MIG welding and MAG welding are given below in table format.

Table: Differences between MIG welding and MAG welding

| MIG welding | MAG welding |

|---|---|

| MIG welding is one type of GMAW process that utilizes inert gases (Ar or He) as shielding gas. | MAG welding is another type of GMAW process that utilizes a mixture of inert and active (O2, CO2) gases as shielding gas. |

| No mechanical or chemical property changes due to shielding gas remains stable. | Shielding gas can alter mechanical and chemical properties of weld bead by inducing various elements on it. |

| Inert gas cylinder is costlier and thus MIG welding is also costlier. | Shielding gas is comparatively cheaper and thus MAG welding is economical. |

| This process is suitable for welding non-ferrous materials like aluminum. | It is suitable for welding of ferrous metals, especially stainless steel. |

Characteristics of shielding gas: As the name suggests, metal inert gas (MIG) welding utilizes only inert gas like argon or helium. Such gases remain stable even at extreme arc temperature. Metal active gas (MAG) welding utilizes a mixture of inert gas and active gases as shielding gas. Such active gas mainly includes oxygen and carbon di-oxide. The mixing proportion between inert and active gases can significantly vary based on many parameters like base metal and its thickness, filler metal, root gap, welding polarity, intended properties of weld bead, etc. Sometimes environmental condition also governs this proportion.

Capability of altering properties of weld bead: Inert shielding gases remain stable during welding and thus do not induce any chemical elements on weld bead. However, active gases can break down under extreme arc temperature and can subsequently induce relevant chemical elements on weld bead. This leads to change in chemical and mechanical properties of joint. For example, while joining low carbon steel (like mild steel) using carbon di-oxide rich shielding gas, carbon inclusion may occur and this can enhance surface hardness of joint. Therefore, MIG welding cannot alter weld bead properties; while, MAG can do the same.

Cost of shielding gas and application area: In GMAW, shielding gas flow rate in the order of 10 – 20L/min is utilized. Cylinders, filled with industrially pure shielding gas, is comparatively costlier and thus MIG welding is one costlier process. It is primarily used for welding non-ferrous materials like aluminum. Oxygen based active gas is not favored when parent materials are non-ferrous because of high chances of oxidation. In this sense, MAG is economical and preferred for welding of ferrous metals, especially stainless steel.

Scientific comparison among metal active gas (MAG) and metal inert gas (MIG) welding is presented in this article. The author also suggests you to go through the following references for better understanding of the topic.

- Metal Inert Gas (MIG) / Metal Active Gas (MAG) Welding by linde-gas.com.

- What is the difference between MIG and MAG by twi-global.com.